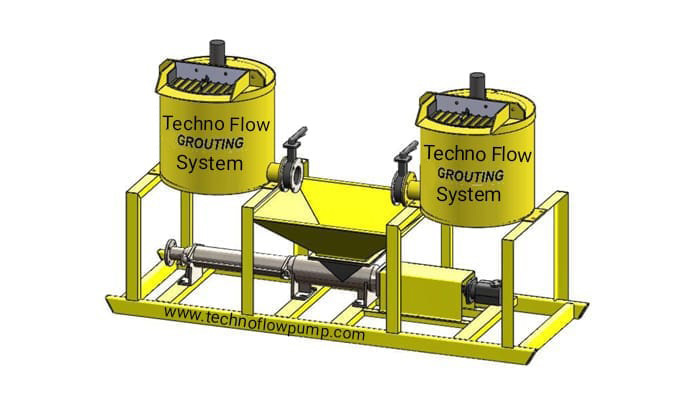

Techno Flow Grout Pumps & Grouting System

Product Details:

| Pump Type | Grouting System |

| Power Source | Electric |

| Material | Mild Steel, Cast Iron |

| Power | 1-2 Kw |

| Maximum Viscosity to be handled | 1000000 Cp |

| Brand | Techno Flow |

| Voltage | 415V |

| Surface Finish | Color Coated |

| Discharge Pressure | Upto 36 bar |

By keeping track with the modern trends, we are bringing forward a wide series of Grout Pumps to our valued patrons.

Other Details:

- Cement Sand Slurry grouting for DAM

- Positive Displacement. Non-Clogging

- Capacity to handle high viscous media

- Capacity to handle highly abrasive media

- Mobile – Trolley mounted version available to replace one place to other place

- Large counter hopper to stock the media

- Directly coupled to a geared motor as well as Belt Drive

- Latest & modified designed of PC pump to handle viscous, Non-viscous, abrasive & N-abrasive slurry / media for filter, dosing & transfer application

OUR PRODUCTS

- Barrel Emptying Pump

- Close Coupled Screw Pump Series-TECC

- Electronic / Electromagnetic Dosing Pump

- Hygienic Screw Pump Series TEF

- Industrial & Chemical Screw Pump Series-TEI

- Industrial Mixing Agitator

- Mechanical Seals

- Multi Spring Mechanical Seal

- Nylon Sev Pump / Bhujiya Making Pump Machine

- Plunger Pump

- Screw Pump Rotor

- Screw Pump Rotor Stator

- Screw Pump Spares Parts

- Single Spring Mechanical Seal

- Skid Mounted Dosing System

- Techno Flow Barrel Emptying Pump Series-TEB

- Techno Flow Grout Pumps & Grouting System

- Techno Flow Wide Throat Pump Series-TEW

Description

Grouting Pump & Grouting System Latest & modified designed of PC pump to handle viscous, Non-viscous, abrasive & N-abrasive slurry / media for filter, dosing & transfer application. Max. Flow: 150 M3 /Hr. Max. Viscosity to be handled: 100000 Cp Discharge Pressure: Upto 36 bar Cement + Sand Slurry grouting for DAM Positive Displacement. Non-Clogging. Capacity to handle high viscous media. Capacity to handle highly abrasive media. Mobile - Trolley mounted version available to replace one place to other place. Large counter hopper to stock the media. Directly coupled to a geared motor as well as Belt Drive